Multifunctional Materials Research Group

.png)

Overview

In a research space where scientific concepts that were once domiciled in laboratories are being transformed into functional materials and devices, Dr. David Olubiyi Obada’s research group has concentrated on the development, characterization, and testing of multifunctional materials that are naturally existing and specifically engineered. Over the years, the group has been dedicated to engineering and transforming these materials for use in fundamental and advanced research and to fulfill societal needs.

Our research focuses on catalysis, mechanical and crack behaviour of advanced materials such as perovskites, kaolin-based membranes, hydroxyapatite scaffolds, etc. We are most interested in their remarkable physical, chemical, and mechanical properties such as density, porosity, homogenous and heterogeneous morphologies, robust hardness and fracture toughness, and unprecedented barrier properties. We fabricate

3 +

Total Projects56

Total Publications30 +

Supervised Students15 +

JournalsResearch

Vehicular Emissions

Our research on vehicular emissions with associated scenarios like fuel economy and importantly, engine performance is on the development of new emission abatement materials and their application in real-time. In terms of catalyst synthesis and real-time testing of catalytic converters, our experimental work is split between materials synthesis and emissions testing which includes the characterization of the developed materials as it relates to catalytic efficiency and the measurement of vehicle emissions, including hydrocarbons, nitrogen oxides (NOx), carbon monoxide (CO), carbon dioxide (CO2), and evaporative emissions. Catalytic substrates, for instance, ceramics, have been a popular choice for anchoring active catalysts as catalytic converters. The porosity and gas permeability of these substrates, in addition to their mechanical properties, has been a hot topic in the use of these materials. Hence, we have developed low-cost ceramic substrates for catalytic substrate applications using a new pore-forming agent in the process. The porosity embedded in the substrates, the gas permeability rate, and also the mechanical properties were within tolerable limits. We demonstrated that formulations containing the new pore-forming agent can produce ceramic bodies with porosities as high as 67%.

Our research on vehicular emissions with associated scenarios like fuel economy and importantly, engine performance is on the development of new emission abatement materials and their application in real-time. In terms of catalyst synthesis and real-time testing of catalytic converters, our experimental work is split between materials synthesis and emissions testing which includes the characterization of the developed materials as it relates to catalytic efficiency and the measurement of vehicle emissions, including hydrocarbons, nitrogen oxides (NOx), carbon monoxide (CO), carbon dioxide (CO2), and evaporative emissions. Catalytic substrates, for instance, ceramics, have been a popular choice for anchoring active catalysts as catalytic converters. The porosity and gas permeability of these substrates, in addition to their mechanical properties, has been a hot topic in the use of these materials. Hence, we have developed low-cost ceramic substrates for catalytic substrate applications using a new pore-forming agent in the process. The porosity embedded in the substrates, the gas permeability rate, and also the mechanical properties were within tolerable limits. We demonstrated that formulations containing the new pore-forming agent can produce ceramic bodies with porosities as high as 67%.

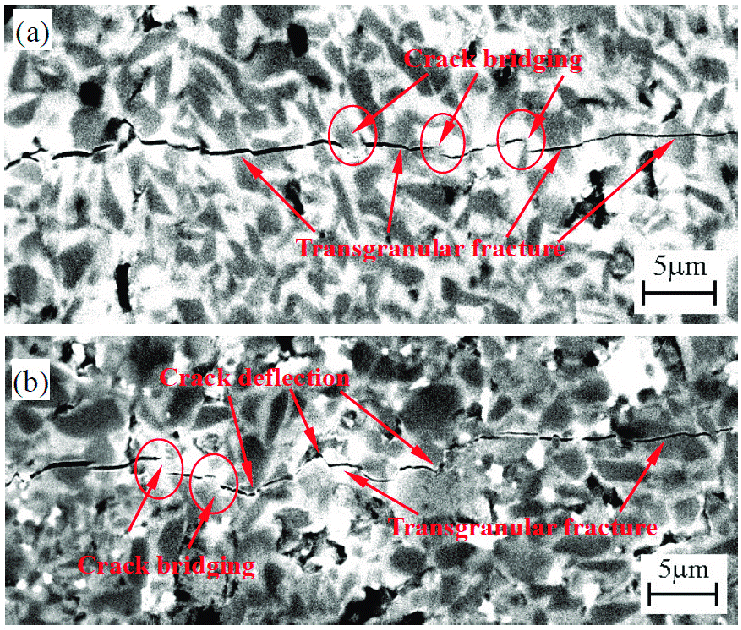

Investigating the Mechanical Properties of Porous Ceramic Membranes

Our approach combines using the acoustic emission system to investigate the modes of crack propagation in the ceramic bodies during the cooling stage of firing. We insert alumina rods (Ø 3 mm) into the samples which serve as a waveguide. Afterward, a piezoelectric sensor (Ø 3 mm) is glued to the other end of the rod for the measurement of cracks by monitoring the wave backscattering. By introducing pore-forming agents into the ceramic bodies, we have demonstrated that it is possible to suppress the cracks from the sintered ceramics

Our approach combines using the acoustic emission system to investigate the modes of crack propagation in the ceramic bodies during the cooling stage of firing. We insert alumina rods (Ø 3 mm) into the samples which serve as a waveguide. Afterward, a piezoelectric sensor (Ø 3 mm) is glued to the other end of the rod for the measurement of cracks by monitoring the wave backscattering. By introducing pore-forming agents into the ceramic bodies, we have demonstrated that it is possible to suppress the cracks from the sintered ceramics

Solar Cells

We are currently exploiting the use of perovskites, both inorganic and hybrid, to develop solar cells for photovoltaic applications. We are considering alternatives to the high-temperature processed titanium dioxide (TiO2) in the regular architecture of perovskite solar cells (PSCs). Most commonly, this is a solution-processed hybrid organic-inorganic tin or lead halide-based material. Perovskite solar cells (PSCs) are forecast to be extremely cheap to scale up, making them a very attractive option for commercialization especially in Nigeria where there is an acute shortage of electricity with an abundance of sunlight. Thus, our work on cerium oxide (CeOx) based PSCs would aim to render the low temperature solution-processed CeOx electron transport layer for high-performance perovskite solar cells with improved stability.

We are currently exploiting the use of perovskites, both inorganic and hybrid, to develop solar cells for photovoltaic applications. We are considering alternatives to the high-temperature processed titanium dioxide (TiO2) in the regular architecture of perovskite solar cells (PSCs). Most commonly, this is a solution-processed hybrid organic-inorganic tin or lead halide-based material. Perovskite solar cells (PSCs) are forecast to be extremely cheap to scale up, making them a very attractive option for commercialization especially in Nigeria where there is an acute shortage of electricity with an abundance of sunlight. Thus, our work on cerium oxide (CeOx) based PSCs would aim to render the low temperature solution-processed CeOx electron transport layer for high-performance perovskite solar cells with improved stability.

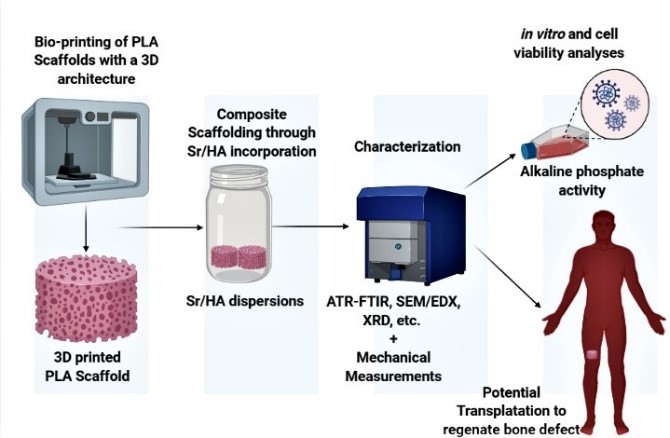

Biomaterials for Tissue Engineering

>Biowastes are a source of environmental hazard and efforts to valorize these biowastes into useful biomaterials is a good approach to mitigating these problems. Human bone, as a complex composite biomaterial gains its ability to resist fractures through its bone quality and these features deteriorate with advanced age or osteoporosis and fragility fractures. One of the treatment protocols for osteoporosis is the development of mechanically stable and porous osteoconductive hydroxyapatite scaffolds which allows bone cells to grow and promote bone regeneration. However, a fundamental problem of hydroxyapatite is its low fracture toughness (KIc) and porosity (when prepared at elevated temperatures). Essentially, the lower the fracture toughness and porosity, the lower is the clinical application of the hydroxyapatite because these parameters define the critical stress level and proliferation of bone cells respectively. Therefore, hydroxyapatite scaffolds need to undergo mechanical competence and porosity tests in addition to biological evaluations before it is cleared for biomedical applications.

>Biowastes are a source of environmental hazard and efforts to valorize these biowastes into useful biomaterials is a good approach to mitigating these problems. Human bone, as a complex composite biomaterial gains its ability to resist fractures through its bone quality and these features deteriorate with advanced age or osteoporosis and fragility fractures. One of the treatment protocols for osteoporosis is the development of mechanically stable and porous osteoconductive hydroxyapatite scaffolds which allows bone cells to grow and promote bone regeneration. However, a fundamental problem of hydroxyapatite is its low fracture toughness (KIc) and porosity (when prepared at elevated temperatures). Essentially, the lower the fracture toughness and porosity, the lower is the clinical application of the hydroxyapatite because these parameters define the critical stress level and proliferation of bone cells respectively. Therefore, hydroxyapatite scaffolds need to undergo mechanical competence and porosity tests in addition to biological evaluations before it is cleared for biomedical applications.

Sustainable Engineering Pedagogy

Our goal is to develop useful and sustainable Engineering pedagogies to complement the traditional teaching pedagogies.

Our goal is to develop useful and sustainable Engineering pedagogies to complement the traditional teaching pedagogies.

For this reason, we present a new pedagogy, CACPLA (Communicate, Active, Collaborate, Problem-solving, Learning, Assessment) considering the peculiarities in sub-Saharan Africa, to facilitate a transition from our conventional classroom teaching to complete virtual instruction for some of our engineering subjects.

AVAILABLE POSITIONS

We are currently looking for motivated Ph.D., Masters, Undergraduate, and Internship students to join the group at Ahmadu Bello University, Zaria, Nigeria. Send me an email if you are interested in applying.

Contact UsWorkShop

Nano-Materials: Characterization and Application,Artificial Intelligence Materials Modelling and Trends in Carbon Free Fuels

Read More

Read More